Introduction to Elbow Making Machine

Aug 01, 2024

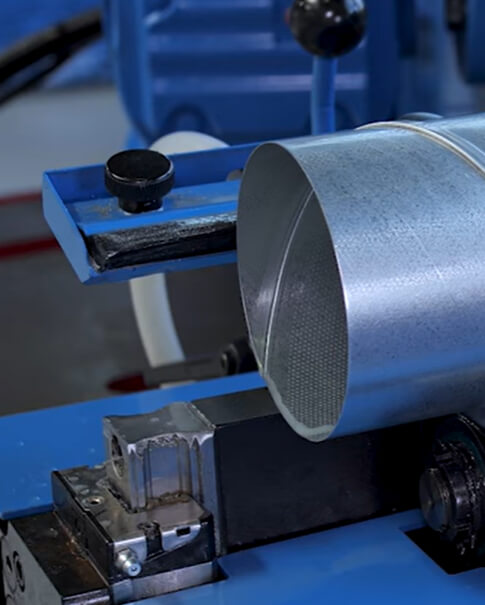

Elbow Making Machine is a special equipment specially used for processing sheet metal circular pipes and butt jointing on round pipe elbows. The following is a detailed introduction to the Elbow Making Machine:

1. Product Overview

Name: Elbow Making Machine, also known as round pipe elbow making machine.

Usage: Mainly used for processing metal pipe fittings and bending them into various shapes with different angles and curvatures to adapt to different use occasions. Xiami elbow machines are widely used in furniture, doors and windows, kitchenware, pipes, air conditioning and HVAC and other fields.

2. Product features

(1)Reasonable structure and stable performance: Elbow Making Machine adopts a scientific and reasonable structural design to ensure that the machine has stable performance during operation and can continue to work efficiently.

(2)Easy to operate: The machine's operating interface is simple and clear, and users can bend metal pipe fittings through simple operations.

(3)Efficient and practical: Elbow Making Machine has high-efficiency processing capabilities and can quickly complete the bending processing of metal pipe fittings and improve production efficiency.

(4)High processing precision: The machine can maintain high precision during the processing process, ensuring that the processed metal pipe fittings are accurate in size and angle.

(5)High sealing: The air duct after bite has high sealing, strong and durable, and can meet the needs of various complex working conditions.

3. Working principle

The working principle of the Elbow Making Machine is mainly based on the principles of physical mechanics. The rotating device is rotated by the drive of the motor, which generates centrifugal force to throw the material outward and transport it to the curved part of the machine body. At the same time, the wind generated by the centrifugal fan accelerates the movement speed of the material, forming a strong material flow, thereby realizing the bending process of metal pipe fittings.

4. Application fields

Elbow Making Machine are widely used in many fields, including but not limited to:

(1)Air conditioning and HVAC: In air conditioning and HVAC systems, Elbow Making Machines are used to make elbows of various shapes to meet the needs of pipe connections.

(2)Chemical industry and building materials: In the chemical industry and building materials industry, Elbow Making Machine can be used to transport cement, powdery materials, etc.

(3)Furniture, doors and windows: In furniture and door and window manufacturing, Elbow Making Machine can be used to make components such as metal frames.

5.Precautions for use

(1)Pre-operation inspection: Safety inspection of the Elbow Making Machine is required before operation to ensure that the machine is in good working condition.

(2)Safety protection: Protective equipment such as gloves and goggles are required to prevent injuries during operation.

(3)Standard operation: Follow the instruction manual to avoid damage to the machine or loss of processing accuracy caused by improper use.

(4)Maintenance: Perform regular maintenance on the Elbow Making Machine to extend its service life and maintain its good working condition.

To sum up, the Elbow Making Machine is an efficient and practical metal pipe fitting processing equipment with wide application prospects and market demand.

6.How to use Elbow Making Machine

1. Preparation

First, you need to prepare the metal pipe fittings that need to be processed, and measure the position where they need to be bent to ensure that the bending position is accurate. At the same time, appropriate elbows and bend positions need to be inserted to ensure that the bending angle and shape meet the requirements.

2. Operation steps

Next, you can start operating the Elbow Making Machine.

(1) Insert the metal pipe fitting onto the roller of the bending machine, and then secure the pipe fitting firmly.

(2) Adjust the bending angle and degree of the elbow machine to make it meet the requirements. The bending position and angle can be adjusted by rotating the handle of the bending machine.

(3) Start the Elbow Making Machine, bend the metal pipe fittings, and repeatedly adjust the position and angle of the elbow machine as needed until the bending requirements are met.

(4) After completing the bending, close the Elbow Making Machine and take out the bent metal pipe fittings.